SHE Management

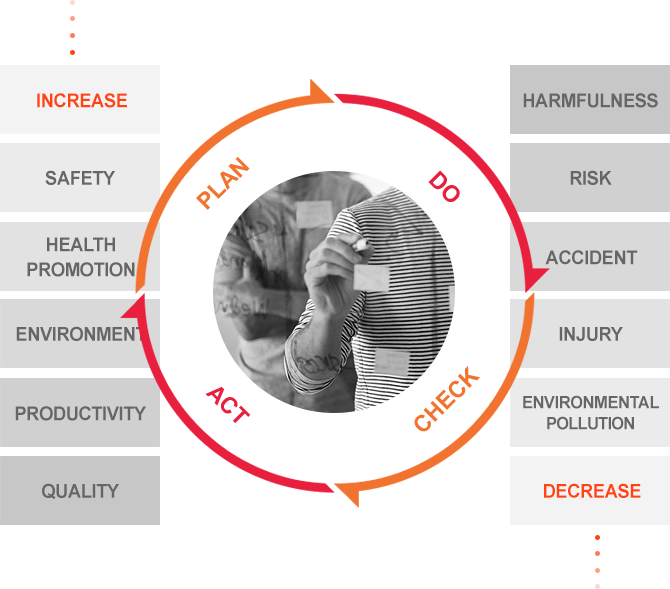

Hanwha TotalEnergies Petrochemical places

the SHE as a top priority for its management

activities and strives to build

the world's best safety culture.

VISION

Hanwha TotalEnergies Petrochemical recognizes that the SHE is a key element of management that supports the company's well-being and growth, while at the same time recognizing that it is a source of abundant life for human society. All employees are thoroughly taking the initiative in following the SHE principle, carrying out their duties.

Safety Health Environment Quality Charter

Hanwha-Total recognizes that safety, health, environment and quality (hereinafter called “SHEQ”) are the key factors for the source of bountiful life of mankind as well as the prosperity and growth of the company.

In that sense Hanwha-Total is committed to act in accordance with the highest standards and the best practices of SHEQ, striving to apply the policy to all activities as below:

- 1. Regulatory compliance The company shall set up strict standards on internal control of SHEQ based on legislative requirements in and outside the country, and will strive to operate with rigor and demonstrate exemplarity to keep improving SHEQ management system.

- 2. Continuous improvement The company shall periodically monitor, evaluate and review SHEQ management system to consistently improve and ensure any management activity in providing products and services which answer to customers’ requirements and do not have any negative significant impact on resources, environmental footprint, and climate.

- 3. Accident prevention The company shall be dedicated to prevent any injury, impact to employees, their subcontractors-partners and other stakeholders, any damage to properties, by forging safety culture. Company will focus on procedures, process safety, creating a safe and healthy work place; Risks on products and services will be controlled, and the company will ensure an appropriate response plan to any incident, which will be updated and regularly tested.

- 4. Participation Each and every team member, at all level, and partners shall be trained and aware of importance of SHEQ and engaged in SHEQ-related activities voluntarily to contribute to the success of SHEQ system. An improvement suggestion system to collect ideas from employees and partners will be put in place.

- 5. Open management The company shall be transparent in opening records of SHEQ to not just employees at all levels but to shareholders, partnered companies, customers, local residents and other stakeholders, and will communicate with them sincerely.

- Hanwha TotalEnergies Petrochemical Co., Ltd.

- President & JRD laurentius na

- EVP & JRD Thierry Boulfroy

SAFETY, HEALTH & ENVIRONMENT MANAGEMENT SYSTEM

Hanwha TotalEnergies Petrochemical conducts systematic SHE management activities by introducing and applying various home and abroad SHE management systems; and continues to review and improve the effectiveness and appropriateness of the system through periodic inspection and certification by external experts. Based on this, Hanwha strives to build a world-class safety culture by enacting Hanwha TotalEnergies Petrochemical's own regulations, rules and standards.

- Safety & Health Manual: SIO45001

- Process safety management system: PSM, SMS

- Environment management system: ISO 14001

- Advanced safety management system: ISRS

- Hanwha Group safety environment system: ECO-YHES

- Excellent workplace for health promotion system

INDIVIDUAL SAFETY MANAGEMENT

Considering each individual as a valuable family member, Hanwha TotalEnergies Petrochemical actively carries out various activities, such as education, inspection activities, safety campaigns, communication, and health management in order to create a safe workplace for all employees and partners.

- Customized Education by Tier

- Safety education for new workers

- Safety leadership education

- On-line education

- Safety experience education

- On-site Inspection to Ensure Work Safety

- Establishing constant inspection system

- Joint inspection between management and labor

- Employee safety guidelines

- Top5 golden rules

- Safety Campaign to Improve Safety Culture

- Campaign to improve drinking culture

- Joint safety campaign with high-ranking officials

- Challenge! No-accidents Golden Bell

- Safety drama

- Communication on for safety and health information delivery

- Occupational safety and health committee

- Safety environment day

- Safety manager regular council

- World day for safety

- Healthcare for Workers

- Work environment measurement

- MSDS

- General examination / special examination

- Prevention of musculoskeletal disorders

SMART SAFETY MANAGEMENT

Hanwha TotalEnergies Petrochemical is leading SMART safety management technology to keep up with era of the 4th industrial revolution. In particular, Hanwha TotalEnergies Petrochemical is making an effort to prevent major disasters by developing its own remote monitoring system (RMS) through wearable airbag and portable CCTV to mitigate impacts on important parts of the body in case of a fall.

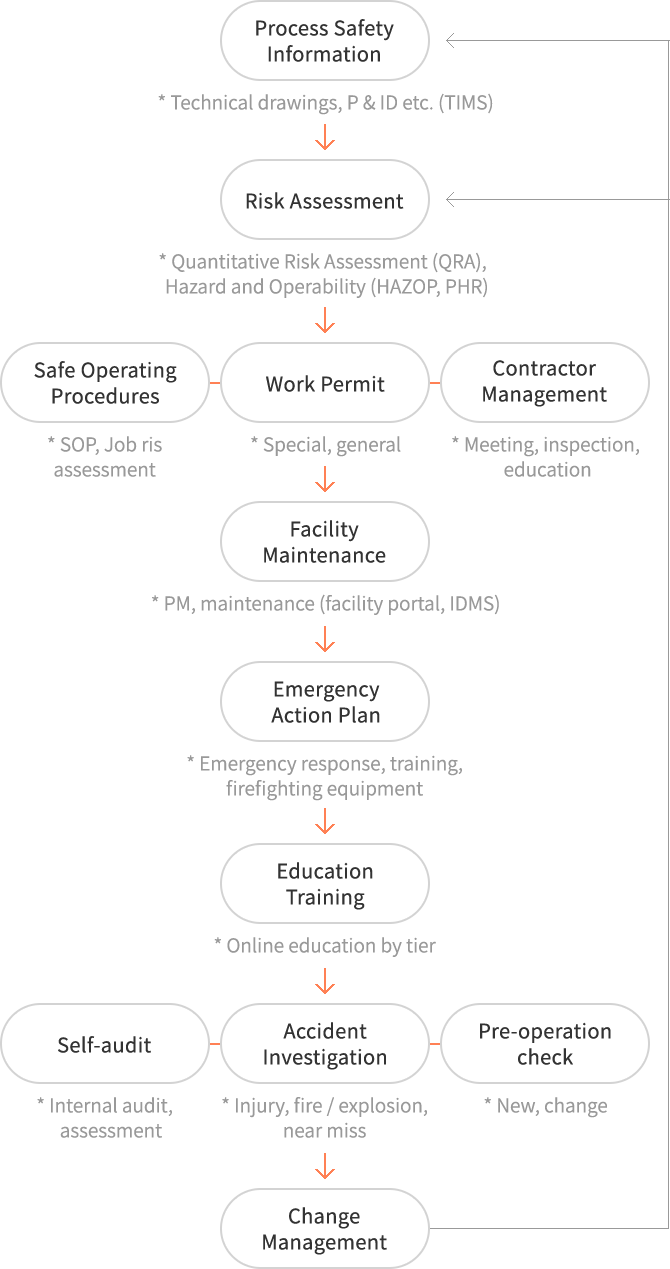

PROCESS SAFETY MANAGEMENT SYSTEM

Process accidents at petrochemical plants can lead to fire, explosion, leakage of hazardous materials, and serious loss of life and property. Hanwha TotalEnergies Petrochemical is making every effort to prevent serious occupational accidents by establishing a process safety management system based on the 12 elements of PSM, identifying risks, recognizing risks, and controlling them.

CONTINGENCY PLAN

Hanwha TotalEnergies Petrochemical is operating a contingency organization for each plant in an effort to deal with accidents such as fire, explosion, gas or oil leak. Hanwha TotalEnergies Petrochemical also is doing its utmost to minimize damage in case of an emergency by establishing a contingency scenario and conducting emergency drills on regular basis where every employee participates.

- Disaster prevention center : Monitoring the plant 24 hours a day

- Establishing automatic fire detection system in all plants

- Surveillance focused on dangerous area with Closed Circuit TV

- Establishing the system to jointly cope with emergencies

- Securing emergency medical technicians

- Operate fire drill field independently

PREVENTION OF ENVIRONMENTAL POLLUTION

Hanwha TotalEnergies Petrochemical continues to try to reduce pollutants by managing sources that can cause environmental pollution, preventing environmental pollution accidents, and complying with environmental laws and regulations.

- Natural park operation on plant site

- Installation of denitrification equipment for boiler and power generation facilities (SCR : Selective Catalytic Reduction, FGR : Flue Gas Recirculation)

- Installation of arsenic acid emitting materials incinerator (RTO : Regenerative Thermal Oxidizer, VCU : Vapor Combustion Unit)

- Construction of LDAR (Leak Detection and Repair) System for the management of arsenic acid emission facilities in every plant

- Installation of wastewater treatment plant storage cover and QBR (Quick Bio-Reactor)

- Emergency shut-off of rain waterway and operation of rain water separation facility

- Management of the whole waste process and implementation of continuous reduction activities through system

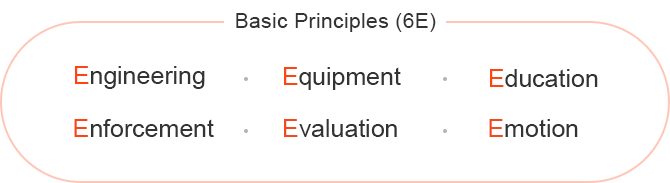

CHEMICAL MANAGEMENT

Hanwha TotalEnergies Petrochemical operates CheMiR (Chemical Management Including REACH) to build a database of domestic and overseas regulatory information for each chemical substance; and actively copes with chemical accident by identifying and responding to harmful factors in advance throughout management of all chemical substances.